ENERGY EFFICIENCY: THE VISIT OF I.T.S. UMBRIA ACADEMY

Sterling has activated a fruitful collaboration with I.T.S. Umbria Academy,non-university higher technological training institute.

We hosted the students of the "Energy Efficiency" course of the ITS UMBRIA ACADEMY, which focuses its training offer on non-university higher technological training. The mission of ITS Academy is to offer young people from high schools a valid opportunity to continue their post-diploma studies.

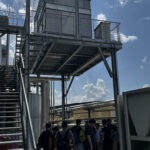

The students of the course visited the thermal plant, the water plant, the compressed air plant and the evaporative tower, thus having the opportunity to see our commitment to sustainability and energy efficiency, that is to say the set of operations which allows you to optimize the relationship between energy needs and level of emissions, exploiting energy sources in an optimal way.

We hosted the students of the "Energy Efficiency" course of the ITS UMBRIA ACADEMY, which focuses its training offer on non-university higher technological training. The mission of ITS Academy is to offer young people from high schools a valid opportunity to continue their post-diploma studies.

The students of the course visited the thermal plant, the water plant, the compressed air plant and the evaporative tower, thus having the opportunity to see our commitment to sustainability and energy efficiency, that is to say the set of operations which allows you to optimize the relationship between energy needs and level of emissions, exploiting energy sources in an optimal way.

Specifically, the introduction of the new evaporative tower which is at the service of the entire production department, allows the cooling of a circuit with an electricity consumption about 10 times lower than that required by a normal refrigeration unit and improves the quality of the crystallization processes. This has also given rise to important economic repercussions linked - precisely - to energy saving.

Specifically, the introduction of the new evaporative tower which is at the service of the entire production department, allows the cooling of a circuit with an electricity consumption about 10 times lower than that required by a normal refrigeration unit and improves the quality of the crystallization processes. This has also given rise to important economic repercussions linked - precisely - to energy saving.